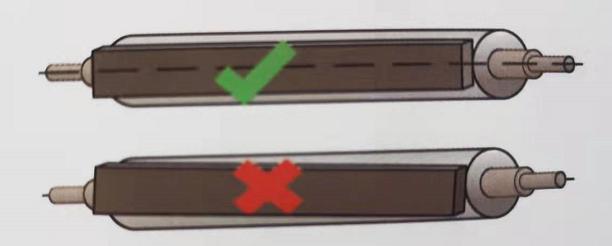

Ukuvaleka kwamaseli e-anilox roller empeleni kuyisihloko esingenakugwenywa kakhulu ekusetshenzisweni kwama-anilox roller, Ukubonakaliswa kwako kuhlukaniswe ngamacala amabili: ukuvaleka kobuso be-anilox roller (Umfanekiso.1) kanye nokuvinjelwa kwamaseli e-anilox roller (Umfanekiso. 2).

Umfanekiso .1

Umfanekiso .2

Uhlelo olujwayelekile lwe-inki ye-flexo luqukethe igumbi le-inki (uhlelo lokuphakela i-inki elivaliwe), i-anilox roller, i-plate cylinder kanye ne-substrate. Kuyadingeka ukusungula inqubo yokudlulisa i-inki eqinile phakathi kwe-inki Chamber, amaseli e-anilox roller, ubuso bamachashazi epuleti lokuphrinta kanye nobuso be-substrate ukuze kutholakale amaphrinti ekhwalithi ephezulu. Kule ndlela yokudlulisa i-inki, izinga lokudlulisa i-inki kusuka ku-anilox roll kuya ebusweni bepuleti cishe lingama-40%, ukudluliselwa kwe-inki kusuka kupuleti kuya ku-substrate cishe kungama-50%, Kungabonakala ukuthi ukudluliselwa okunjalo kwendlela ye-inki akuyona ukudluliselwa okulula ngokomzimba, kodwa inqubo eyinkimbinkimbi ehlanganisa ukudluliselwa kwe-inki, ukomisa i-inki, kanye nokuqedwa kabusha kwe-inki; Njengoba ijubane lokuphrinta lomshini wokuphrinta we-flexo lishesha kakhulu, le nqubo eyinkimbinkimbi ngeke nje ibe yinkimbinkimbi kakhulu, kodwa futhi nokuphindaphinda kokuguquguquka ekudlulisweni kwendlela ye-inki kuzoshesha kakhulu; Izidingo zezakhiwo zomzimba zemigodi nazo ziya ziphakama kakhulu.

Ama-polymer anendlela yokuxhumanisa asetshenziswa kabanzi kuma-inki, njenge-polyurethane, i-acrylic resin, njll., ukuthuthukisa ukunamathela, ukumelana nokuklwebheka, ukumelana namanzi kanye nokumelana namakhemikhali kwengqimba ye-inki. Njengoba izinga lokudlulisa i-inki kumaseli e-anilox roller lingama-40% kuphela, okusho ukuthi, iningi le-inki emaseli empeleni lihlala phansi kwamaseli phakathi nenqubo yonke yokuphrinta. Ngisho noma ingxenye ye-inki ishintshwa, kulula ukwenza ukuthi i-inki iqedwe kumaseli. Ukuxhumanisa i-resin kwenziwa ebusweni be-substrate, okuholela ekuvinjweni kwamaseli e-anilox roll.

Kulula ukuqonda ukuthi ubuso be-anilox roller buvinjiwe. Ngokuvamile, i-anilox roller isetshenziswa ngendlela engafanele, ukuze uyinki uphole futhi uxhumeke ebusweni be-anilox roller, okuholela ekuvinjweni.

Kwabakhiqizi be-anilox roll, ucwaningo kanye nentuthuko yobuchwepheshe bokumboza nge-ceramic, ukuthuthukiswa kobuchwepheshe bokusetshenziswa kwe-laser, kanye nokuthuthukiswa kobuchwepheshe bokwelashwa kobuso be-ceramic ngemuva kokuqoshwa kwe-anilox rolls kunganciphisa ukuvaleka kwamaseli e-anilox roll. Njengamanje, izindlela ezivame ukusetshenziswa ukunciphisa ububanzi bodonga lwe-mesh, ukuthuthukisa ukushelela kodonga lwangaphakathi lwe-mesh, kanye nokuthuthukisa ukuqina kwe-ceramic coating.

Kumabhizinisi okunyathelisa, isivinini sokomisa sikayinki, ukuncibilika kabusha, kanye nebanga ukusuka endaweni yokunyathelisa kuya endaweni yokunyathelisa nakho kungalungiswa ukuze kuncishiswe ukuvaleka kwamaseli e-anilox roller.

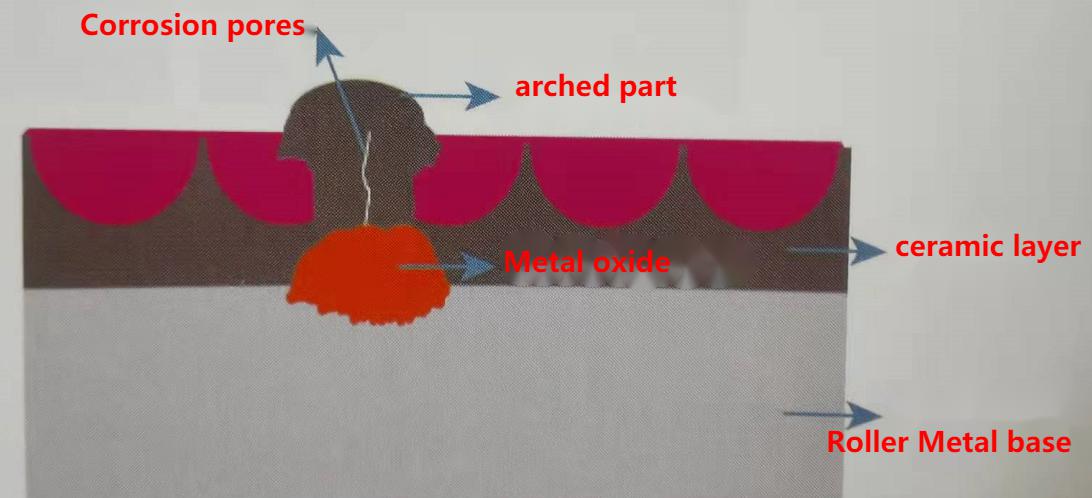

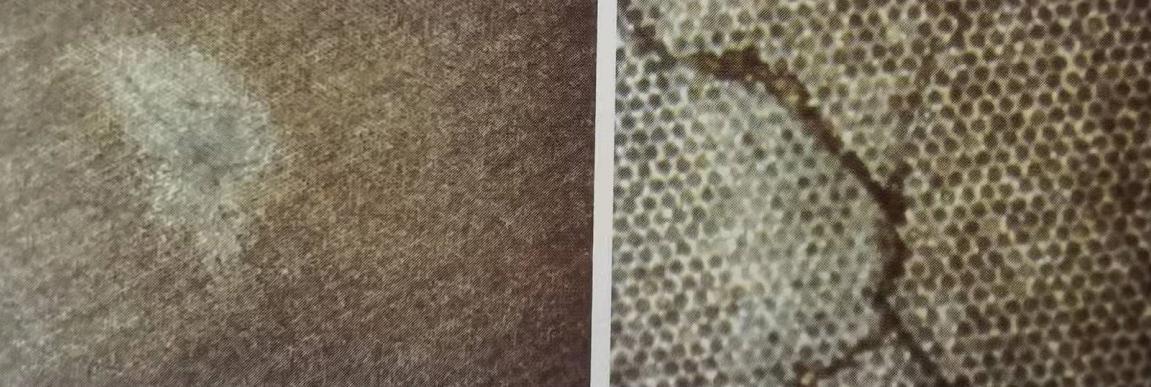

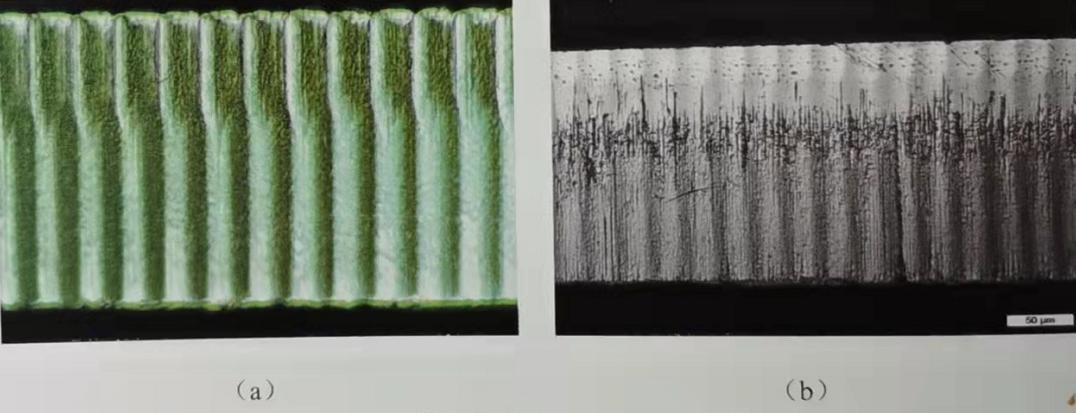

Ukugqwala

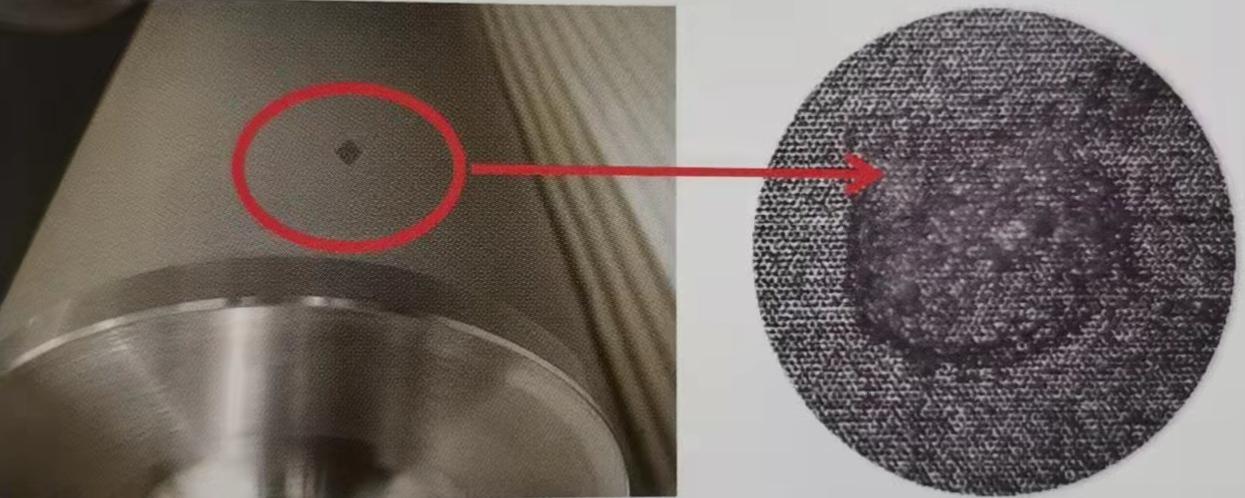

Ukugqwala kubhekisela esimweni sokuvela okufana namachashazi ebusweni be-anilox roller, njengoba kuboniswe kuMfanekiso 3. Ukugqwala kubangelwa yi-ejenti yokuhlanza engena engqimbeni engezansi eceleni kwesikhala se-ceramic, igqwala i-roller eyisisekelo yensimbi engezansi, futhi iphule ungqimba lwe-ceramic ngaphakathi, okubangela umonakalo ku-anilox roller (Isithombe 4, Umfanekiso 5).

Umfanekiso 3

Umfanekiso 4

Umfanekiso 5 ukugqwala ngaphansi kwe-microscope

Izizathu zokwakheka kokugqwala yilezi ezilandelayo:

① Izimbobo zengubo zikhulu, futhi uketshezi lungafinyelela i-base roller ngama-pores, okubangela ukugqwala kwe-base roller.

② Ukusetshenziswa kwesikhathi eside kwezinto zokuhlanza ezifana nama-asidi aqinile nama-alkali aqinile, ngaphandle kokugeza ngesikhathi esifanele kanye nokomisa umoya ngemva kokusebenzisa.

③ Indlela yokuhlanza ayilungile, ikakhulukazi ekuhlanzeni imishini isikhathi eside.

④ Indlela yokugcina ayilungile, futhi igcinwa endaweni enomswakama isikhathi eside.

⑤ Inani le-pH likayinki noma izithasiselo liphezulu kakhulu, ikakhulukazi uyinki osekelwe emanzini.

⑥ I-anilox roller iyathinteka ngesikhathi sokufakwa kanye nenqubo yokuyihlukanisa, okuholela ekushintsheni kwegebe lesendlalelo se-ceramic.

Ukusebenza kokuqala kuvame ukunganakwa ngenxa yesikhathi eside phakathi kokuqala kokugqwala kanye nomonakalo wokugcina we-anilox roll. Ngakho-ke, ngemuva kokuthola isenzakalo sokugoba kwe-ceramic anilox roller, kufanele uxhumane nomhlinzeki we-ceramic anilox roller ngesikhathi ukuze uphenye imbangela ye-arch.

Imihuzuko ejikelezayo

Ukuklwebheka kwama-anilox rolls kuyizinkinga ezivame kakhulu ezithinta impilo yama-anilox rolls.(I-1965)isithombe 6)Kungenxa yokuthi izinhlayiya eziphakathi kwe-anilox roller kanye ne-doctor blade, ngaphansi kwesenzo sokucindezela, ziphula i-ceramics engaphezulu kwe-anilox roller, futhi zivule zonke izindonga ze-mesh ohlangothini lokunyathelisa olugijimayo ukuze kwakheke umsele. Ukusebenza kokunyathelisa ukubonakala kwemigqa emnyama.

Umfanekiso 6 I-Anilox roll enemihuzuko

Inkinga eyinhloko yokuklwebheka ukushintsha kwengcindezi phakathi kwe-drug blade kanye ne-anilox roller, ukuze ingcindezi yokuqala yobuso nobuso ibe yingcindezi yendawo; futhi isivinini esikhulu sokuphrinta sibangela ingcindezi ukuthi ikhuphuke kakhulu, futhi amandla okubhubhisa ayamangalisa. (Isithombe 7)

Umfanekiso 7 imihuzuko enzima

imihuzuko evamile

imihuzuko emincane

Ngokuvamile, kuye ngesivinini sokuphrinta, imihuzuko ethinta ukuphrinta izokwakheka ngemizuzu emi-3 kuya kweyi-10. Kunezici eziningi ezishintsha lokhu kucindezela, ikakhulukazi kusukela ezicini eziningana: i-anilox roller uqobo, ukuhlanzwa nokugcinwa kohlelo lwe-doctor blade, ikhwalithi kanye nokufakwa kanye nokusetshenziswa kwe-doctor blade, kanye nokukhubazeka komklamo wemishini.

1. i-anilox roller uqobo

(1) Ukwelashwa kobuso be-ceramic anilox roller akwanele ngemva kokuqopha, futhi ubuso buqinile futhi kulula ukuklwebha i-scraper kanye ne-blade ye-scraper.

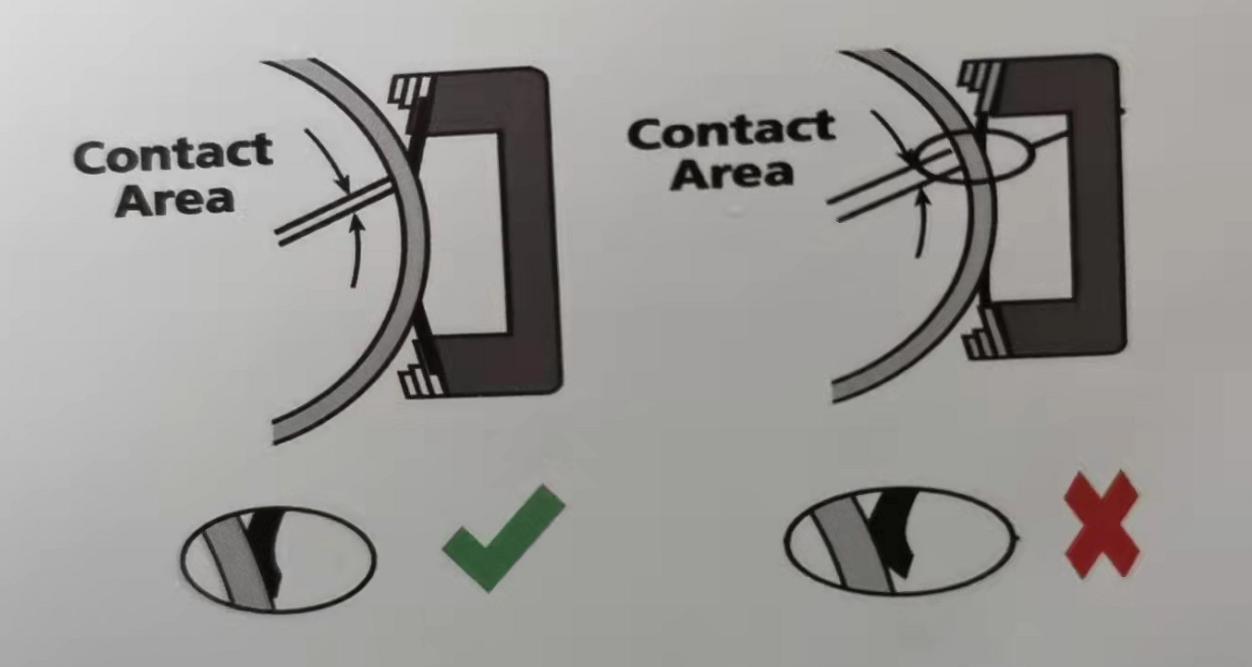

Indawo yokuxhumana ne-anilox roller ishintshile, yandisa ingcindezi, yandisa ingcindezi, futhi yaphula i-mesh esimweni sokusebenza ngesivinini esikhulu.

Ubuso be-roller eqoshiwe bakha imihuzuko.

(2) Umugqa wokupholisha ojulile uyakhiwa ngesikhathi senqubo yokupholisha nokugaya kahle. Lesi simo sivame ukuba khona lapho umqulu we-anilox ulethwa, futhi umugqa opholishiwe kancane awuthinti ukuphrinta. Kulesi simo, ukuqinisekiswa kokuphrinta kudingeka kwenziwe emshinini.

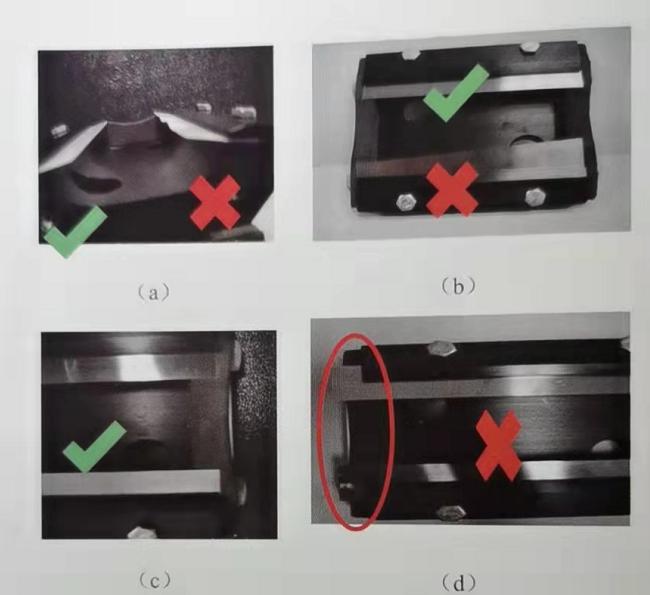

2. ukuhlanzwa nokugcinwa kohlelo lwe-drug blade

(1) Kungakhathaliseki ukuthi izinga le-chamber doctor blade liyalungiswa, i-chamber doctor blade enezinga eliphansi izobangela ukucindezeleka okungalingani. (Isithombe 8)

Umfanekiso 8

(2) Kungakhathaliseki ukuthi igumbi le-drey blade ligcinwa liqonde phezulu, igumbi le-inki elingaqondile lizokwandisa ubuso bokuthintana kwe-blade. Empeleni, lizobangela umonakalo ngqo ku-anilox roller. Isithombe 9

Umfanekiso 9

(3) ukuhlanzwa kwesistimu ye-drug blade yegumbi kubaluleke kakhulu, Vimbela ukungcola ukuthi kungangeni ohlelweni lwe-inki, olubhajwe phakathi kwe-drug blade ne-anilox roller. okubangela izinguquko ekucindezelweni. Uyinki owomile nawo uyingozi kakhulu.

3. Ukufakwa nokusetshenziswa kwe-blade kadokotela

(1) Faka i-chamber doctor blade ngendlela efanele ukuqinisekisa ukuthi i-blade ayonakali, i-blade iqondile ngaphandle kwamagagasi, futhi ihlanganiswe kahle nesiphathi se-blade, njenge

Njengoba kuboniswe kuMfanekiso 10, qiniseka ukuthi ugcina ingcindezi ilingana ebusweni be-anilox roller.

Umfanekiso 10

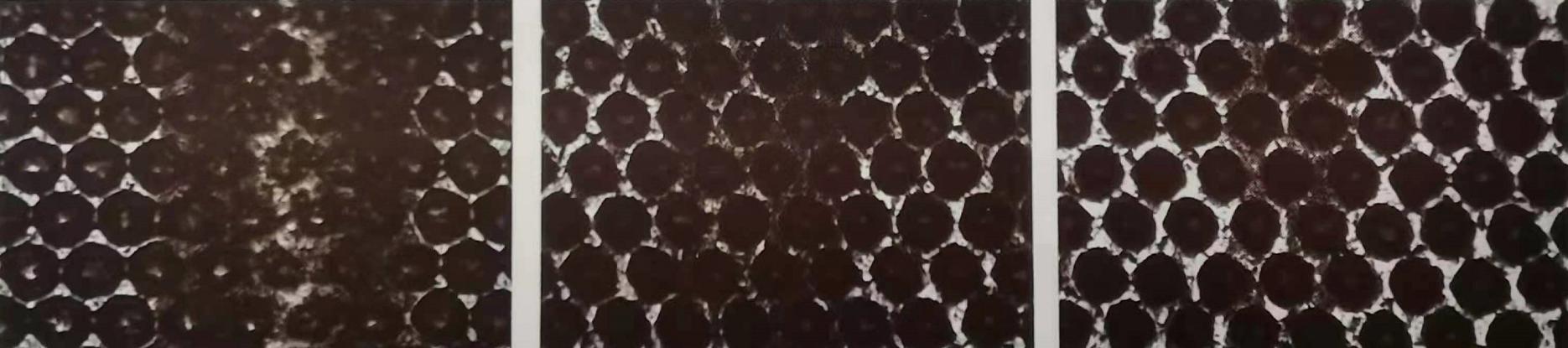

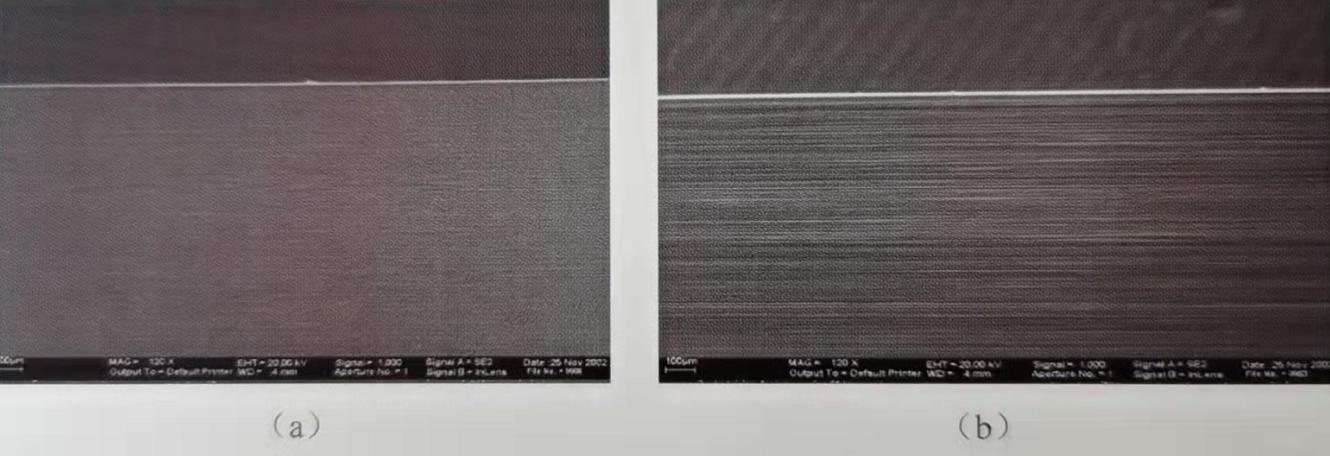

(2) Sebenzisa izikrufu zekhwalithi ephezulu. Insimbi yesikrufu yekhwalithi ephezulu inesakhiwo sama-molecule esiqinile, njengoba kuboniswe kuMfanekiso 11 (a), ngemva kokuguguleka Izinhlayiya zincane futhi ziyafana; isakhiwo sama-molecule sensimbi yesikrufu yekhwalithi ephansi asiqinile ngokwanele, kanti izinhlayiya zinkulu ngemva kokuguguleka, njengoba kuboniswe kuMfanekiso 11 (b) obonisiwe.

Umfanekiso 11

(3) Shintsha ummese we-blade ngesikhathi. Uma ushintsha, naka ukuvikela umphetho wommese ekushayweni. Uma ushintsha inombolo yomugqa ehlukile ye-anilox roller, kufanele ufake ummese we-blade. Izinga lokuguguleka kwe-anilox roller enezinombolo zomugqa ezahlukene alihambisani, njengoba kuboniswe kuMfanekiso 12, isithombe sesobunxele isikrini senombolo yomugqa ophansi Ukugaywa kommese we-blade kummese we-blade Isimo sobuso bokugcina obonakele, isithombe esingakwesokudla sibonisa isimo sobuso bokugcina obugugukile be-anilox roller ebala umugqa ophezulu kummese we-blade. Ubuso bokuxhumana phakathi kwe-drug blade ne-anilox roller enamazinga okuguguleka angalingani buyashintsha, okubangela izinguquko zokucindezela kanye nokuklwebheka.

Umfanekiso 12

(4) Ingcindezi ye-squeegee kufanele ibe lula, kanti ingcindezi enkulu ye-squeegee izoshintsha indawo yokuxhumana kanye ne-engeli ye-squeegee kanye ne-anilox roller, njengoba kuboniswe kuMfanekiso 13. Kulula ukufaka ukungcola, futhi ukungcola okufakiwe kuzobangela imihuzuko ngemva kokushintsha ingcindezi. Uma kusetshenziswa ingcindezi engafanele, kuzoba nemisila yensimbi egugile engxenyeni ephambene ye-scraper eshintshiwe Umfanekiso 14. Uma isiwile, ibanjwa phakathi kwe-scraper ne-anilox roller, okungase kubangele imihuzuko ku-anilox roller.

Umfanekiso 13

Umfanekiso 14

4. amaphutha okuklama kwemishini

Amaphutha okuklama angabangela ukuthi kube nokuklwebheka kalula, njengokungafani phakathi komklamo webhulokhi yeyinki nobubanzi bomqulu we-anilox. Umklamo ongenangqondo we-engeli ye-squeegee, ukungalingani phakathi kobubanzi nobude be-anilox roller, njll., kuzoletha izici ezingaqinisekile. Kungabonakala ukuthi inkinga yokuklwebheka ohlangothini oluzungezile lomqulu we-anilox iyinkimbinkimbi kakhulu. Ukunaka izinguquko ekucindezelweni, ekuhlanzeni nasekugcinweni ngesikhathi, ukukhetha i-scraper efanele, kanye nemikhuba yokusebenza emihle nehlelekile kunganciphisa kakhulu inkinga yokuklwebheka.

Ukushayisana

Nakuba ubulukhuni bezinto zobumba buphezulu, ziyizinto ezibuthakathaka. Ngaphansi komthelela wamandla angaphandle, izinto zobumba kulula ukuziwisa futhi zikhiqize imigodi (Isithombe 15). Ngokuvamile, kuvela amaqhubu lapho kulayishwa futhi kuthululwa ama-anilox rollers, noma amathuluzi ensimbi ewa ebusweni be-roller. Zama ukugcina indawo yokuphrinta ihlanzekile, futhi ugweme ukufaka izingxenye ezincane eduze komshini wokunyathelisa, ikakhulukazi eduze kwethreyi yeyinki kanye ne-anilox roller. Kunconywa ukwenza umsebenzi omuhle we-anilox. Ukuvikelwa okufanele kwe-roller ukuvimbela izinto ezincane ukuthi zingawi futhi zishayisane ne-anilox roller. Lapho kulayishwa futhi kuthululwa i-anilox roller, kunconywa ukuthi uyisonge ngesembozo esivikelayo esiguquguqukayo ngaphambi kokusebenza.

Umfanekiso 15

Isikhathi sokuthunyelwe: Feb-23-2022