Enqubweni yemishini ye-flexographic, ukomisa kancane kweyinki okuholela ekungcoleni kube yinselele eqhubekayo ezinkampanini zokunyathelisa. Lokhu akugcini nje ngokuthinta ikhwalithi yokunyathelisa futhi kwandise imfucuza kodwa futhi kunciphisa ukusebenza kahle kokukhiqiza futhi kungase kulibazise ngisho namashejuli okulethwa. Le nkinga ingaxazululwa kanjani ngempumelelo? Sinikeza ikhambi eliphelele elihlanganisa ukukhethwa kweyinki, ukwenza ngcono inqubo, ukuthuthukiswa kwemishini, kanye nokulawulwa kwemvelo ukuze sikusize uqede ukungcolisa futhi ufeze ukukhiqizwa kokunyathelisa okuzinzile nokusebenza kahle kakhulu.

Enqubweni yemishini ye-flexographic, ukomisa kancane kweyinki okuholela ekungcoleni kube yinselele eqhubekayo ezinkampanini zokunyathelisa. Lokhu akugcini nje ngokuthinta ikhwalithi yokunyathelisa futhi kwandise imfucuza kodwa futhi kunciphisa ukusebenza kahle kokukhiqiza futhi kungase kulibazise ngisho namashejuli okulethwa. Le nkinga ingaxazululwa kanjani ngempumelelo? Sinikeza ikhambi eliphelele elihlanganisa ukukhethwa kweyinki, ukwenza ngcono inqubo, ukuthuthukiswa kwemishini, kanye nokulawulwa kwemvelo ukuze sikusize uqede ukungcolisa futhi ufeze ukukhiqizwa kokunyathelisa okuzinzile nokusebenza kahle kakhulu.

● Ukukhethwa Kweyinki Nokwenza Ifomula Isebenze Kahle – Ukuxazulula Izinkinga Zokomisa Emthonjeni

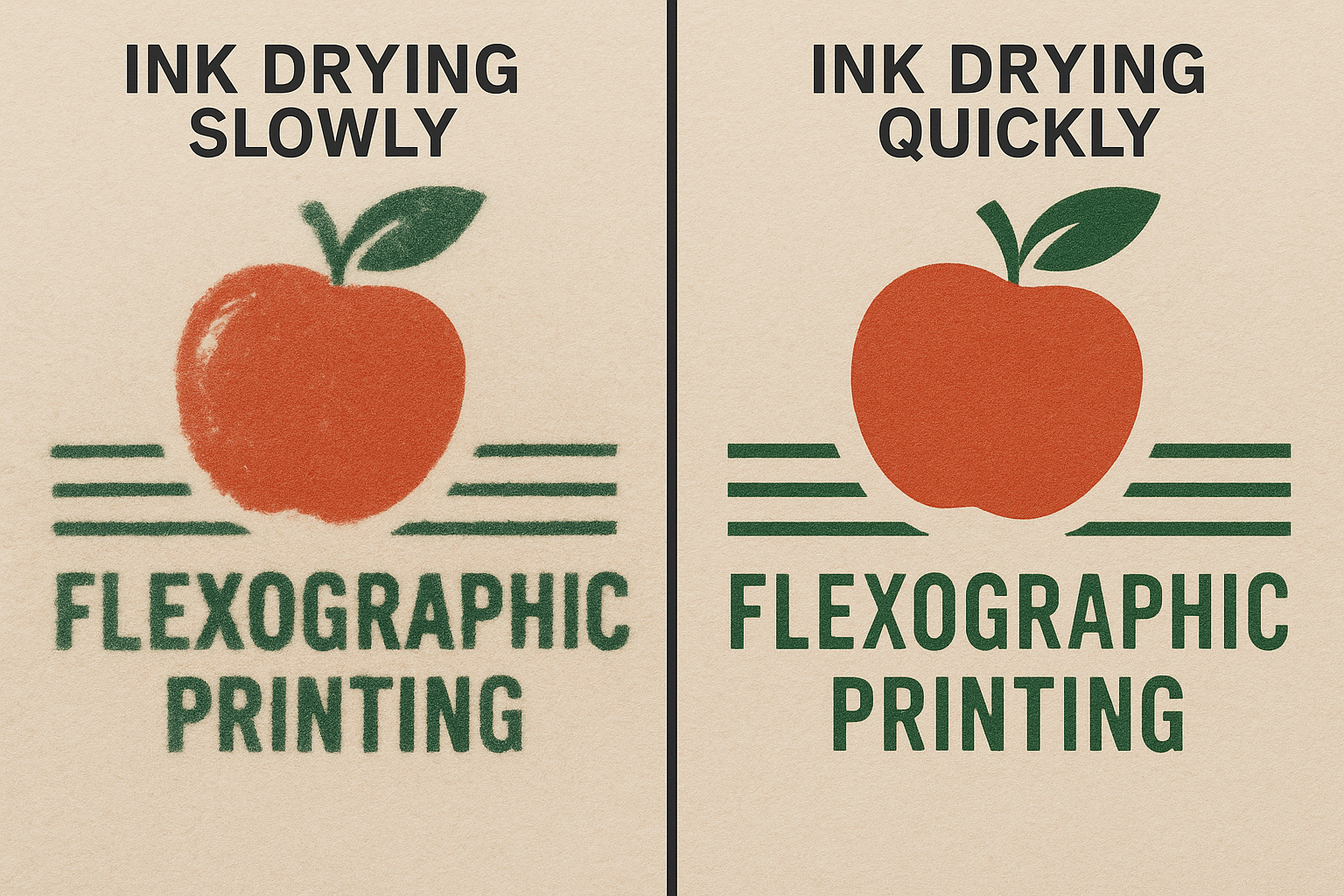

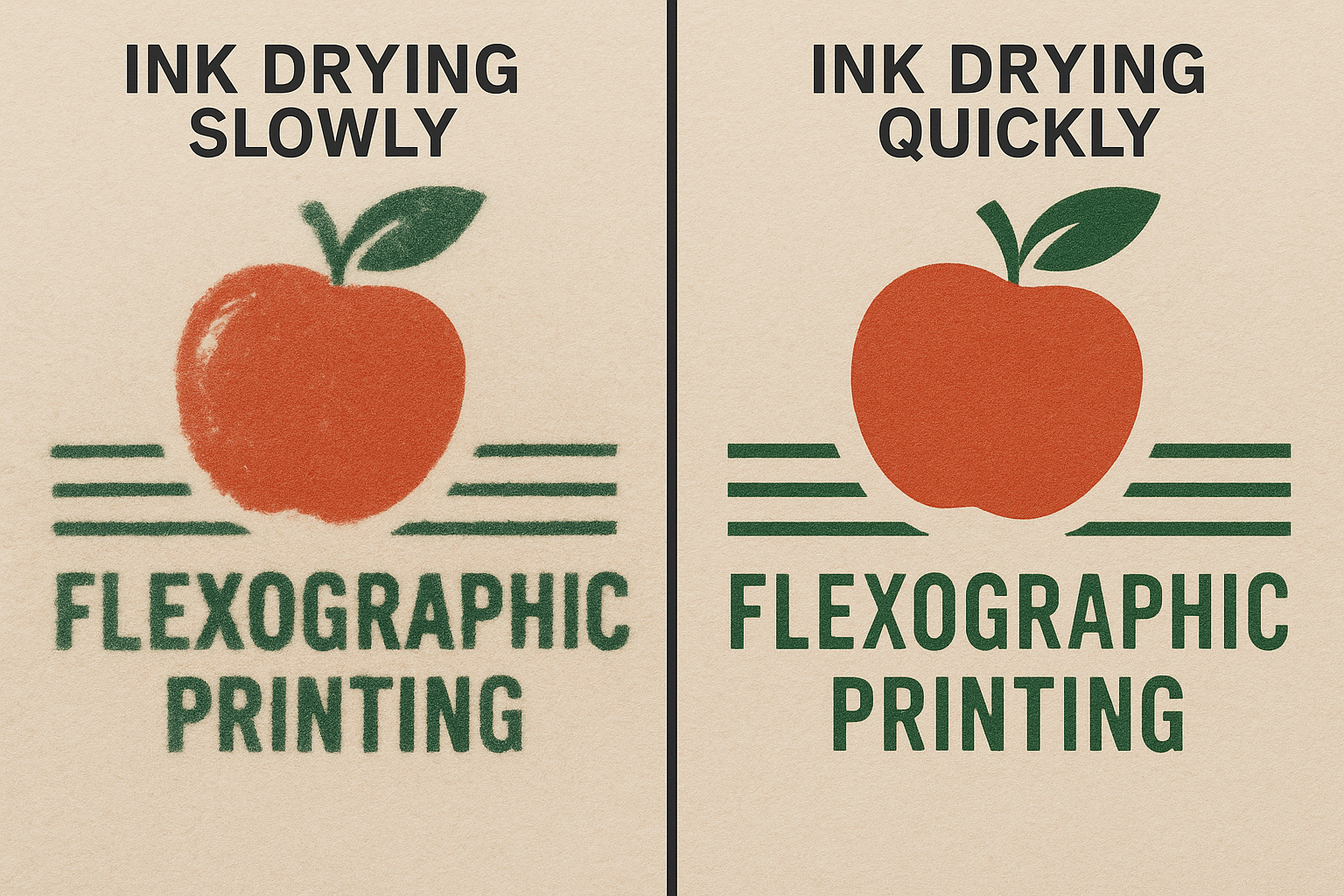

Emishinini yokunyathelisa ye-flexo, ukukhethwa kanye nokwakheka kweyinki kubalulekile ekuxazululeni izinkinga zokomisa. Sincoma uyinki owomisa ngokushesha, njengoyinki osekelwe ku-solvent one-formulations ezishintshashintshayo kakhulu noma uyinki osekelwe emanzini one-accelerators yokomisa. Ukuze uthole isivinini esikhulu sokomisa, uyinki we-UV ohlanganiswe nezinhlelo zokupholisa ze-ultraviolet yiwona ongcono kakhulu. Ukulungisa izilinganiso ze-solvent—njengokwandisa okuqukethwe kwe-ethanol noma i-ethyl acetate—kungathuthukisa ukusebenza kokomisa ngenkathi kugcinwa ukuqina kweyinki. Ngaphezu kwalokho, ukukhetha izithasiselo zokomisa ezifanele (isb., ama-drier e-cobalt/manganese ama-ink owomisa nge-oxidative noma ama-penetrant akhethekile e-substrates ezimuncayo) kuqinisekisa imiphumela emihle kakhulu.

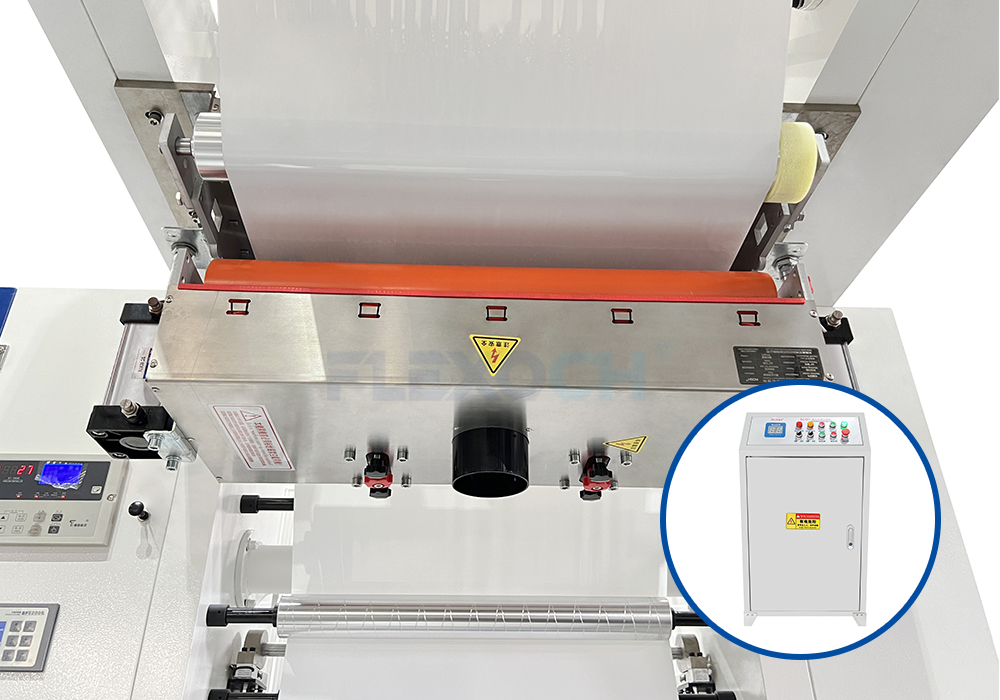

● Ukuthuthukiswa Kwesistimu Yokomisa – Ukuthuthukisa Ukusebenza Kahle

Ukusebenza kwezinhlelo zokomisa emshinini wokunyathelisa we-flexo kuthinta ngqo imiphumela. Hlola njalo ama-dryer ukuqinisekisa ukuthi izinga lokushisa lifanelekile (50–80°C kuma-inki e-solvent, aphansi kancane emanzini) kanye nokugeleza komoya okungavimbelwe. Ngezinhlelo zokusebenza ezidinga amandla, thuthukela ekomiseni kwe-infrared ukuze kusebenze kahle endaweni ethile noma ekuqedeni i-UV ukuze komiswe ngokushesha. Amayunithi okomisa emoyeni obandayo awusizo kakhulu kumafilimu angamunci ukuze kuvinjelwe ukumanziswa kabusha kwe-inki.

● Ukuthuthukisa Inqubo Yokuphrinta – Ukulungisa Amapharamitha Okukhiqiza

Emishinini yokunyathelisa ye-flexographic, ukwenza ngcono amapharamitha okukhiqiza kuthuthukisa kakhulu ukusebenza kahle kokomisa. Ukulawula isivinini sokunyathelisa kubalulekile—isivinini esikhulu sivimbela ukoma okufanele ngaphambi kwesiteshi sokunyathelisa esilandelayo. Lungisa isivinini ngokusekelwe ezicini zeyinki kanye nomthamo wokomisa. Ukuphatha ukujiya kwefilimu yeyinki ngokukhetha kahle i-anilox roller kanye nevolumu yeyinki kuvimbela ukwakheka ngokweqile. Ekunyatheliseni ngemibala eminingi, ukwandisa isikhala sesiteshi noma ukwengeza ama-dryer aphakathi kwesiteshi kwandisa isikhathi sokomisa.

● Ukuzivumelanisa Nemvelo Nezimo Ezingaphansi Kwesakhiwo – Izici Ezibalulekile Zangaphandle

Izimo zemvelo ekusebenzeni kwephrinta ye-flexo zithinta kakhulu ukomisa. Gcina izinga lokushisa lesitolo lingama-20–25°C kanye nomswakama ku-50–60%. Sebenzisa ama-dehumidifier ngezikhathi zomswakama. Ukwelashwa kwangaphambi kwe-substrate (isb., ukwelashwa kwe-corona kwamafilimu e-PE/PET) kuthuthukisa ukunamathela kweyinki futhi kunciphisa amaphutha okomisa.

Ukwelashwa kweCorona

Ukulawula Umswakama

Okokugcina, uhlelo lokulungisa oluqinile luqinisekisa ukuzinza kwesikhathi eside. Hlanza njalo ama-nozzle okomisa kanye nezinto zokushisa, hlola ukuguguleka kwe-anilox roller, bese usebenzisa abahloli bokuqina komoya ukuqapha ikhwalithi yokuphrinta—izinyathelo ezibalulekile zokuvimbela izinkinga ezihlobene nokomisa.

Isikhathi sokuthunyelwe: Meyi-29-2025