Umshini Wokuphrinta we-CI Flexo

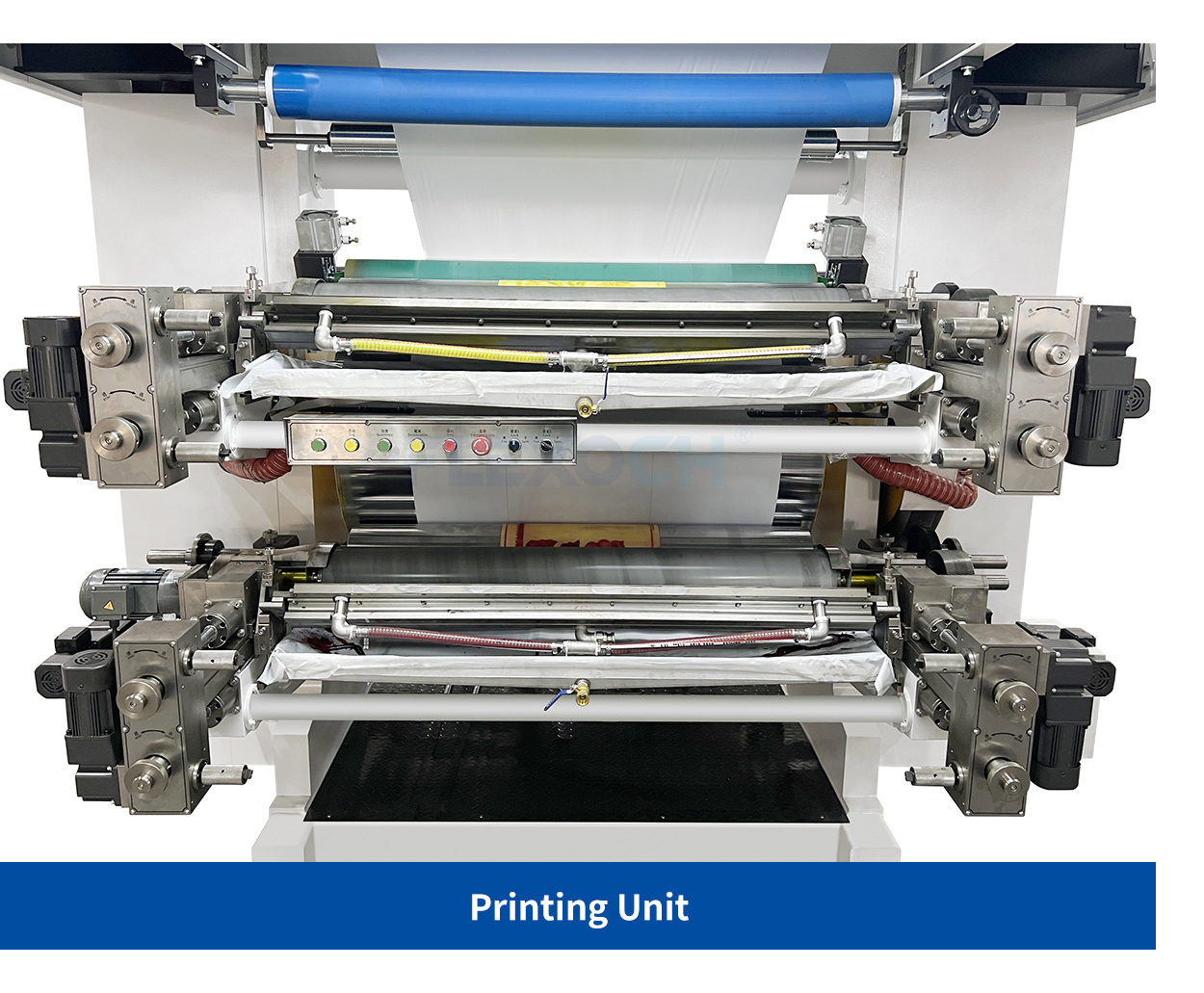

Umshini wokunyathelisa we-CI (Central Impression) we-flexo usebenzisa isigubhu esisodwa esikhulu sokucindezela ukuze ubambe izinto ziqinile ngenkathi yonke imibala iphrinta nxazonke. Lo mklamo ugcina ukungezwani kuzinzile futhi unikeza ukunemba okuhle kakhulu kokubhalisa, ikakhulukazi kumafilimu azwela ukunwebeka.

Isebenza ngokushesha, ayichithi izinto eziningi, futhi ikhiqiza imiphumela yokuphrinta esezingeni eliphezulu—ilungele ukupakisha okuphezulu kanye nezinhlelo zokusebenza ezinembile.

Umshini Wokuphrinta we-Flexo Uhlobo Lwe-Stack Type

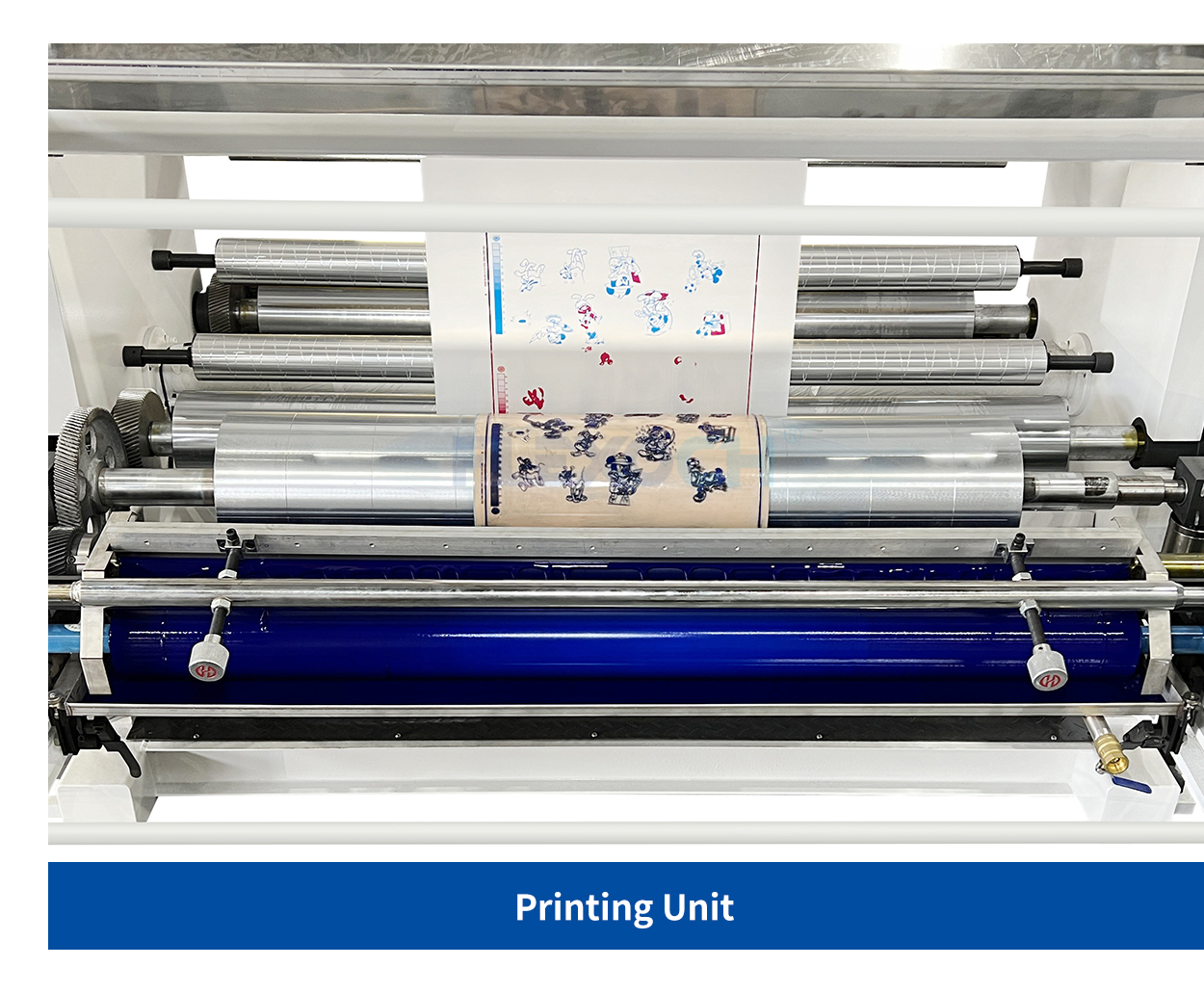

Umshini wokucindezela we-flexo we-stack uneyunithi ngayinye yombala ehlelwe ngokuqondile, futhi isiteshi ngasinye singalungiswa sodwa. Lokhu kwenza kube lula ukusingatha izinto ezahlukene kanye noshintsho lomsebenzi. Isebenza kahle ezinhlotsheni eziningi ze-substrate futhi iwusizo ikakhulukazi ekuphrinteni okunezinhlangothi ezimbili.

Uma udinga umshini oguquguqukayo, ongabizi kakhulu wokupakisha nsuku zonke, umshini wokunyathelisa we-stack flexo uyindlela ewusizo nethembekile.

Kungakhathaliseki ukuthi umshini wokunyathelisa we-CI flexo noma umshini wokunyathelisa we-flexo wohlobo lwe-stack, kungase kube nokungalungi kokubhaliswa kombala, okungathinta ukusebenza kombala kanye nekhwalithi yokunyathelisa yomkhiqizo wokugcina. Izinyathelo ezinhlanu ezilandelayo zinikeza inqubo ehlelekile yokuxazulula inkinga nokuxazulula le nkinga.

1. Hlola Ukuqina Kwemishini

Ukubhaliswa okungalungile kuvame ukubangelwa ukuguguleka kwemishini noma ukuxega. Emishinini yokunyathelisa ye-stack flexo, kufanelekile ukuhlola njalo amagiya, amabheringi, namabhande okushayela axhumanisa iyunithi ngayinye yokunyathelisa, ukuqinisekisa ukuthi akukho ukudlala noma i-offset okungathinta ukuhambisana.

Imishini yokunyathelisa yokubonisa okuphakathi ivame ukuthola ukubhaliswa okuzinzile njengoba yonke imibala inyatheliswa ngedrama eyodwa yokubonisa. Noma kunjalo, ukunemba kusaxhomeke ekufakweni kwesilinda sepuleti efanele kanye nokugcina ukuqina kwewebhu okuzinzile—uma noma yikuphi kuwela, ukuzinza kokubhalisa kuzolimala.

Isincomo:Noma nini lapho amapuleti eshintshwa noma umshini ubungasebenzi isikhathi esithile, phendula iyunithi ngayinye yokuphrinta ngesandla ukuze uzwe noma yikuphi ukumelana okungavamile. Ngemva kokuqeda ukulungisa, qala ukucindezela ngesivinini esiphansi bese uhlola izimpawu zokubhalisa. Lokhu kusiza ukuqinisekisa ukuthi ukuhambisana kuhlala kufana ngaphambi kokukhuphukela esivinini sokukhiqiza esigcwele.

2. Lungiselela ukuhambisana kwe-Substrate

Izingxenye ezincane ezifana nefilimu, iphepha, kanye ne-nonwovens zisabela ngendlela ehlukile ekucindezelweni, futhi lokhu kuhlukahluka kungabangela ukushintsha kokubhalisa ngesikhathi sokuphrinta. Imishini yokunyathelisa ye-CI flexographic ngokuvamile igcina ukucindezelwa okuzinzile futhi ngakho-ke ifaneleka kahle ekusetshenzisweni kwefilimu okudinga ukunemba okuqinile. Imishini yokunyathelisa ye-stack flexo, ngokuphambene, ivame ukudinga ukulungiswa okunembile kwezilungiselelo zokucindezelwa ukuze kugcinwe ukuhambisana.

Isincomo:Uma ubona ukuthi izinto zinwebeka noma zincipha ngokuphawulekayo, nciphisa ukucindezeleka kwewebhu. Ukucindezeleka okuphansi kungasiza ekunciphiseni ushintsho lobukhulu futhi kunciphise ukuhlukahluka kokubhalisa.

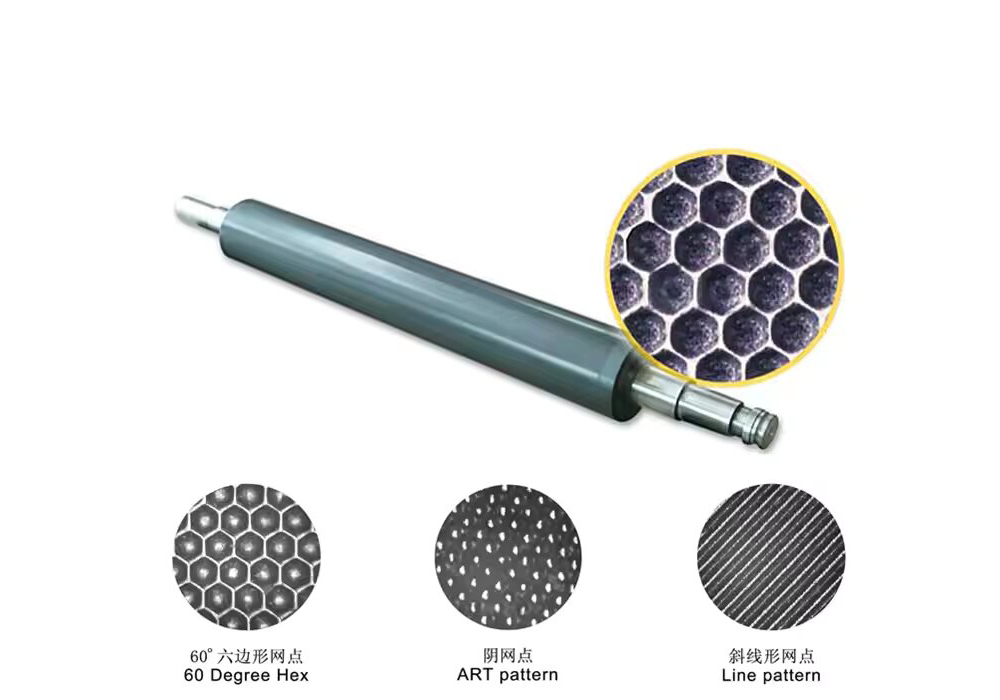

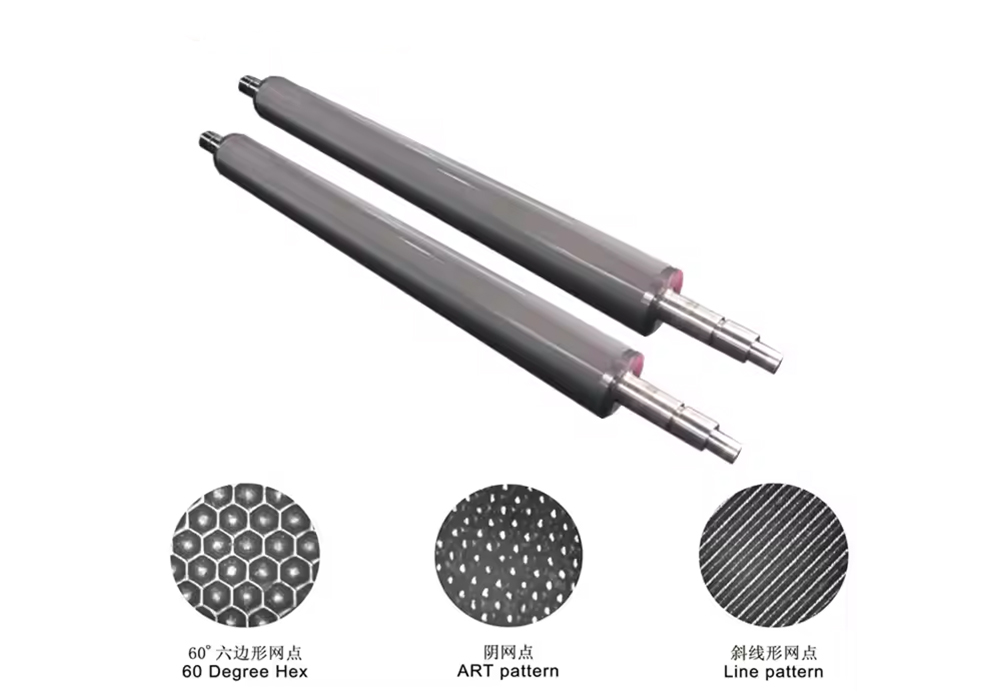

3. Ukulinganisa ipuleti kanye nokuhambisana kwe-Anilox Roll

Izici zepuleti—njengokujiya, ubulukhuni, kanye nokunemba kokuqopha—zinethonya eliqondile ekusebenzeni kokubhalisa. Ukusebenzisa amapuleti anesinqumo esiphezulu kungasiza ekulawuleni ukuzuza kwamachashazi nokuthuthukisa ukuzinza. Inani lomugqa we-anilox roll nalo lidinga ukuhlanganiswa ngokucophelela nepuleti: inani lomugqa eliphakeme kakhulu linganciphisa ivolumu yeyinki, kanti inani eliphansi kakhulu lingabangela uyinki owedlulele kanye nokugcotshwa, kokubili okungathinta ngokungaqondile ukuhambisana kokubhalisa.

Isincomo:Kungcono kakhulu ukulawula inani lomugqa we-anilox roller ku-100 - 1000 LPI. Hlola ukuthi ubulukhuni bepuleti buhlala bufana kuwo wonke amayunithi ukuze ugweme ukwanda kwalokhu kuguquguquka.

4. Lungisa Ukucindezela Kokuphrinta kanye Nohlelo Lokufaka Inki

Uma ingcindezi yokubonisa iphezulu kakhulu, amapuleti okuphrinta angase aguquguquke, futhi le nkinga ivame kakhulu emshinini wokunyathelisa we-flexo wohlobo lwe-stack, lapho isiteshi ngasinye sisebenzisa ingcindezi ngokuzimela. Setha ingcindezi yeyunithi ngayinye ngokwehlukana bese usebenzisa kuphela ubuncane obudingekayo ukuze kudluliselwe isithombe esihlanzekile. Ukuziphatha kwe-inki okuzinzile nakho kudlala indima ebalulekile ekulawuleni ukubhalisa. Hlola i-engeli ye-drug blade bese ugcina i-viscosity efanele ye-inki ukuze ugweme ukusatshalaliswa kwe-inki okungalingani, okungabangela ukushintsha kokubhalisa kwendawo.

Isincomo:Kokubili emshinini wokunyathelisa we-stack type kanye ne-CI flexographic, indlela ye-inki emfushane kanye nokudluliselwa kwe-inki okusheshayo kwandisa ukuzwela ezicini zokomisa. Qaphela isivinini sokomisa ngesikhathi sokukhiqiza, bese ufaka i-retarder uma i-inki iqala ukoma ngokushesha kakhulu.

● Isingeniso Sevidiyo

5. Sebenzisa Amathuluzi Okubhalisa Okuzenzakalelayo kanye Nesinxephezelo

Imishini eminingi yokunyathelisa yesimanje ye-flexographic ifaka izici zokubhalisa okuzenzakalelayo ezilungisa ukuhambisana ngesikhathi sangempela ngenkathi ukukhiqizwa kusebenza. Uma izinkinga zokuvumelanisa zisaqhubeka ngemva kokulungiswa ngesandla, zinike isikhathi sokubukeza amarekhodi emisebenzi angaphambilini. Ukubheka emuva idatha yokukhiqiza yomlando kungaveza amaphethini aphindaphindayo noma ukuphambuka okuhlobene nesikhathi okukhomba imbangela eyinhloko, kukusize wenze izinguquko zokusetha ezigxile kakhulu futhi ezisebenzayo.

Isincomo:Kuma-press asesebenze isikhathi eside, kufanelekile ukuhlola ukulingana okugcwele kuwo wonke amayunithi okuphrinta ngezikhathi ezithile. Lesi sinyathelo sibaluleke kakhulu kuma-press ohlobo lwe-stack flexo, njengoba isiteshi ngasinye sisebenza ngokuzimela futhi ukubhaliswa okuqhubekayo kuncike ekuzigcineni ziqondile njengohlelo oluhlelekile.

Isiphetho

Kungakhathaliseki ukuthi umshini wokunyathelisa we-flexographic oyinhloko noma umshini wokunyathelisa we-flexo wohlobo lwe-stack, inkinga yokubhaliswa kombala ivame ukubangelwa ukusebenzisana kweziguquguquko zemishini, izinto kanye nezinqubo, kunokuba kube yinto eyodwa. Ngokuxazulula izinkinga ngendlela ehlelekile kanye nokulinganisa ngokucophelela, sikholelwa ukuthi ungasiza ngokushesha umshini wokunyathelisa we-flexographic ukuthi uqalise kabusha ukukhiqiza futhi uthuthukise ukuzinza kwesikhathi eside kwemishini.

Isikhathi sokuthunyelwe: Agasti-08-2025