Emkhakheni wokukhiqiza imishini yokunyathelisa ye-flexographic esezingeni eliphezulu, ukunemba nokuthembeka akuveli ngengozi kodwa kuvela ekulawulweni okucophelelayo kwayo yonke imininingwane. Kusukela ekulinganisweni kwezinga le-micrometer lezingxenye eziyinhloko kuya ekuhlolweni kokusebenza okuphelele komshini wonke, siqinisekisa ukuthi yonke iyunithi ehanjiswayo ibonisa ubuhle obuzinzile, obunembile, nobuhlala isikhathi eside, ihlangabezana nezindinganiso ezingenasici.

Impi Yokunemba Kwemishini Ezingxenyaneni Ze-Millimeter

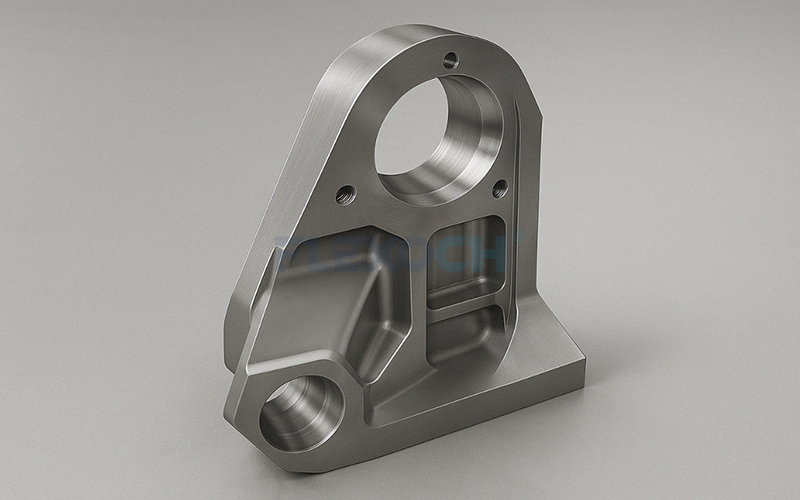

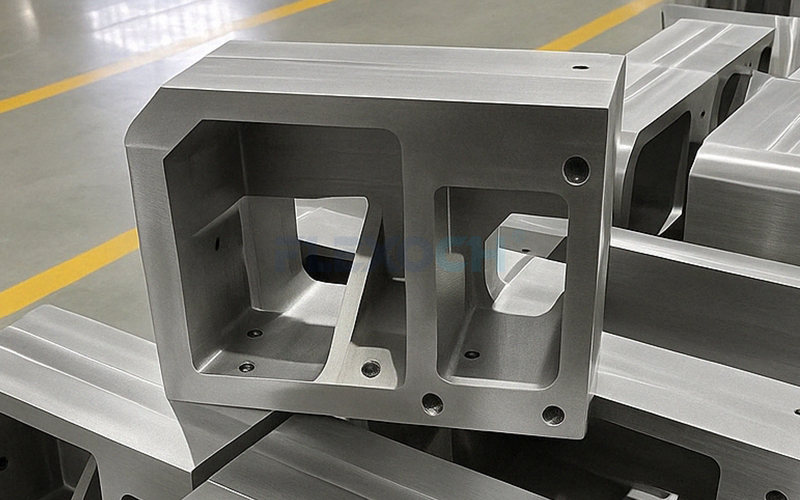

Ekwenzeni imishini yokunyathelisa ye-flexographic, isihluthulelo sokusebenza okuzinzile isikhathi eside sisekuxhumaniseni okunembile kwezakhiwo zemishini. Siyaqonda ukuthi ukuthembeka kwangempela kuqala ngokulawula ngokweqile imininingwane emincane kakhulu—kusukela ku-torque eqondile esetshenziswa kuso sonke isikulufu kuya ekuqinisekisweni kwezinga le-micrometer kwezikhala ze-gear meshing sisebenzisa ukulinganisa ibanga le-laser. Sakha isisekelo sekhwalithi ngezindinganiso ezicishe zibe nzima.

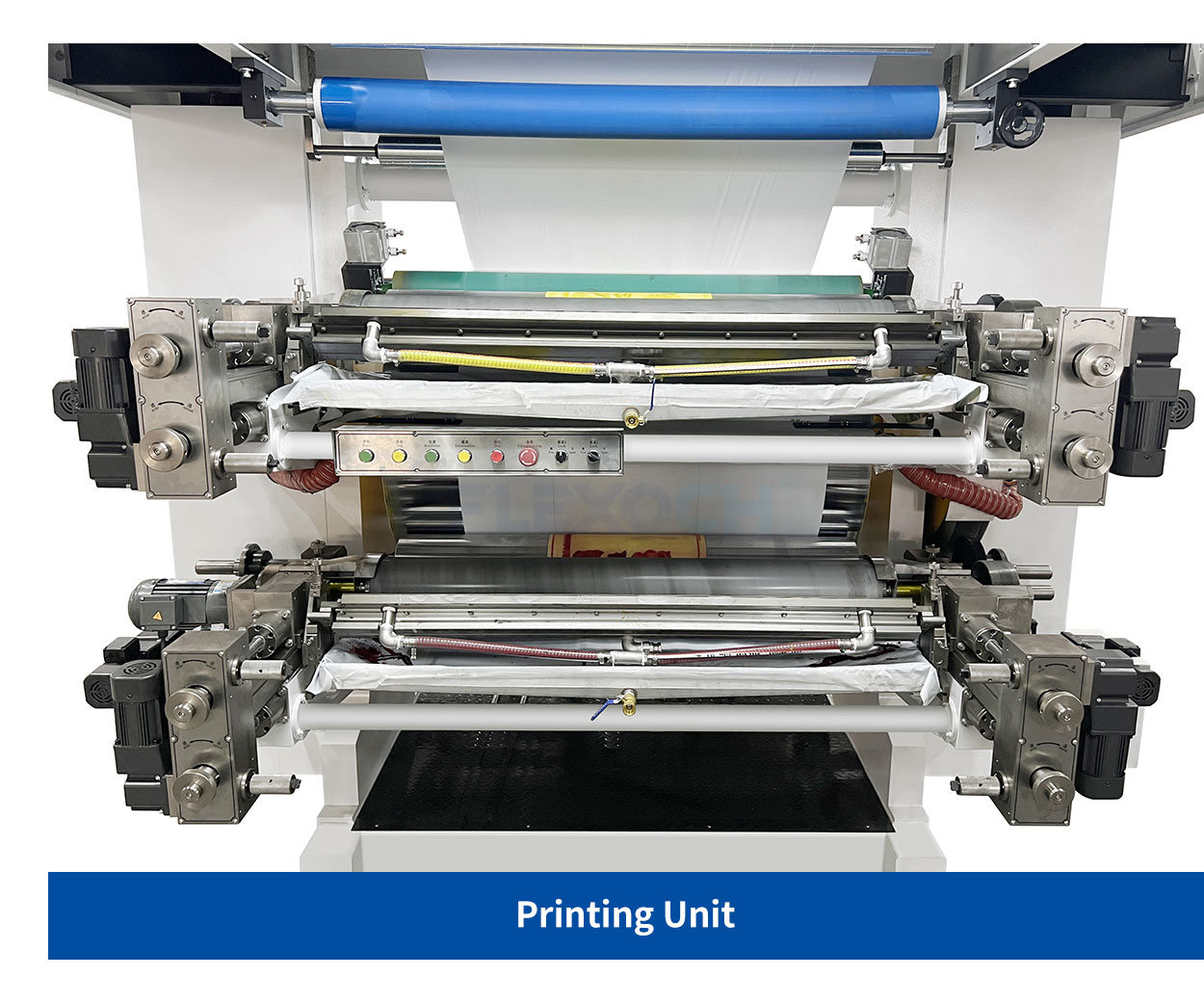

Sisebenzisa izinhlelo zokulinganisa ze-laser ezinembile kakhulu ukuze sihlole ngokugcwele imishini yokunyathelisa ye-flexo. uhlelo lokudlulisa, ukuqinisekisa ukuthi amapharamitha ayinhloko njenge-gear meshing, i-bearing clearance, kanye ne-guide rail parallelism ahlala esesimweni esihle. Ikakhulukazi ngesikhathi sokuhlolwa komthwalo kulingisa ukuphrinta okusheshayo, onjiniyela baqapha njalo ukusebenza kokucindezela kokudlidliza kwemishini ngaphansi kokusebenza isikhathi eside. Ngokuqoqwa kwedatha yesikhathi sangempela kanye nokuhlaziywa, silawula ngokuqinile ubukhulu bokudlidliza kwe-roller ngaphakathi kwe-0.01mm, sisusa izingozi zokubhaliswa kabi noma ukuguguleka komshini okubangelwa ukuphambuka okuncane.

Isiqinisekiso Esizinzile Sokusebenza Kokuphrinta

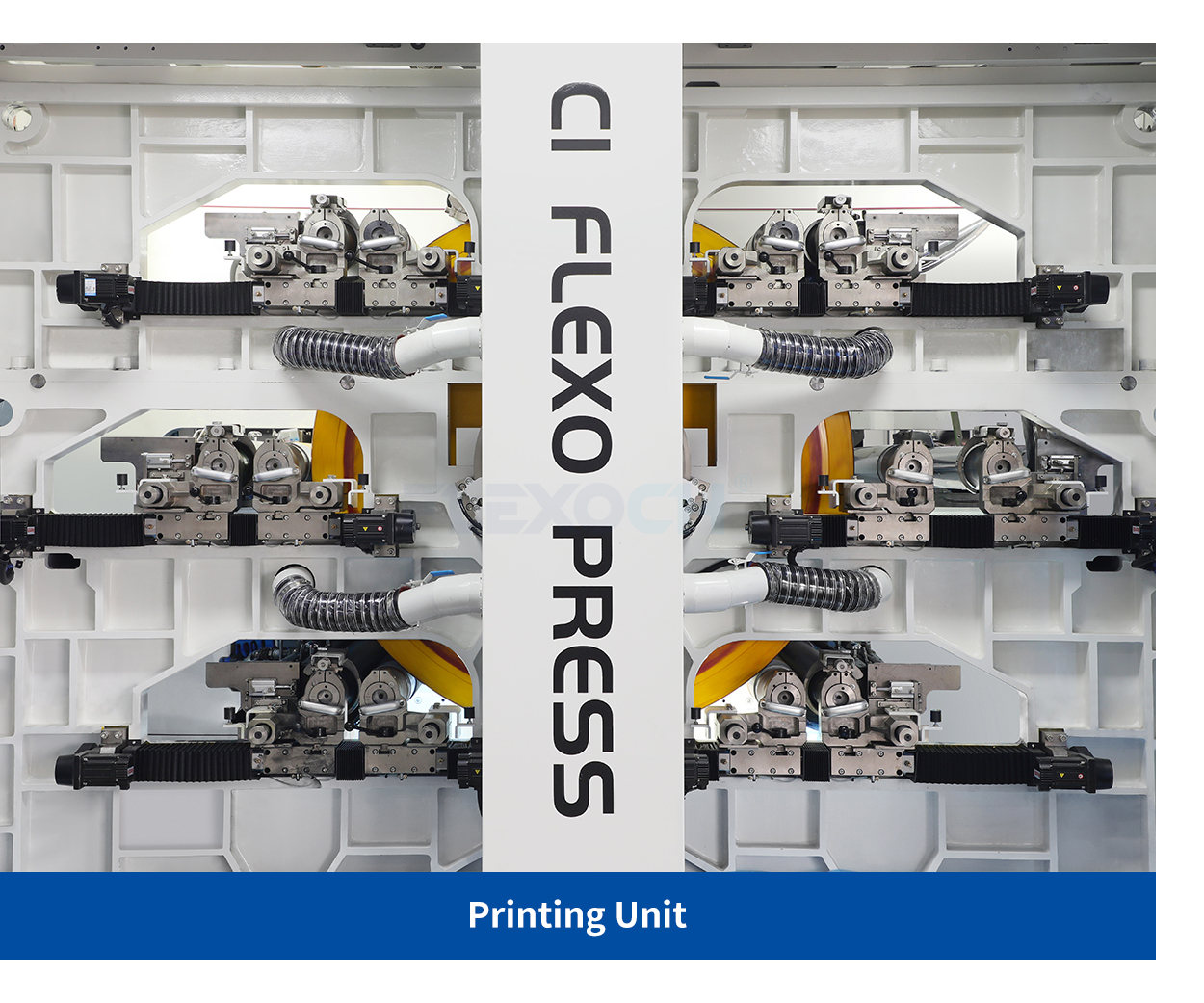

Ukuqina kweyunithi yokunyathelisa yomshini wokunyathelisa we-flexo kunquma ngqo ikhwalithi yokukhipha. I-Changhong isebenzisa izinhlelo zokubona ze-CCD ezinesinqumo esiphezulu ukuqapha ukukhiqizwa kwamachashazi ngesikhathi sangempela, kuhlanganiswe nobuchwepheshe bokulungisa i-closed-loop okuzenzakalelayo, ukuqinisekisa umbala weyinki ofanayo kanye nokubhaliswa okunembile. Ngaphezu kwalokho, kuma-substrates ahlukene (njengefilimu, iphepha, nezinto ezihlanganisiwe), i-workshop yethu yenza ukuhlolwa okuguquguqukayo ngaphansi kwezimo zokukhiqiza zangempela ezilinganisiwe ukuqinisekisa ukuvumelana okuvelele kokunyathelisa kuzo zonke izimo zokusebenza ezahlukahlukene.

Ukuqinisekiswa Kokuthembeka Kwezinhlelo Zokulawula Ezihlakaniphile

Njengesimanjei-flexo yokubonisa komshiniUma siqhubeka nokuhlakanipha, ukuzinza kwezinhlelo zikagesi kubalulekile. Inqubo yokuhlola kaChanghong ifaka phakathi ukuqinisekiswa okujulile kwamamojula ayinhloko njenge-servo drives kanye nokulawulwa kokucindezeleka. Ngokulingisa izimo ezingavamile njengokucima kukagesi okungazelelwe noma ukuphazamiseka kwesignali, sihlola ikhono lokubuyisa ngokushesha kwemishini yokunyathelisa ye-flexo kanye nokusebenza kokulwa nokuphazamiseka. Ngaphezu kwalokho, yonke iyunithi idlula ekuhlolweni kokulingisa kokukhiqiza okuqhubekayo kwamahora angu-48 ngaphambi kokushiya ifektri, ukuqinisekisa ukusebenza okuzinzile ngisho nangaphansi kokusebenza isikhathi eside kwemithwalo ephezulu.

Ukuhlolwa Okuphelele Ngaphansi Kwezimo Ezinzima

Ikhwalithi yangempela kumele imelane nezinselele ezinkulu. Uhlelo lokuhlola lweChanghong alugcini nje ngokugxila ekusebenzeni ngaphansi kwezimo ezijwayelekile kodwa futhi lwenza izivivinyo zokuzivumelanisa nezimo zemvelo ezimweni zokushisa okuphezulu, ezinomswakama ophezulu, kanye nezinothuli, ukuqinisekisa ukusebenza okuzinzile ezifundeni ezahlukene kanye nasezindaweni zokukhiqiza zesizini.

Kusukela ekuqineni kwe-torque yesikulufu esisodwa kuya ebhalansini eliguquguqukayo lomshini wonke wokunyathelisa we-flexo; kusukela ekunembeni kokunyathelisa okukodwa kuya ekuqineni kokusebenza kwesikhathi eside—isinyathelo ngasinye senqubo yokuhlola ye-Changhong sibonisa ifilosofi yokukhiqiza "yokungabi naziphambeko." Siyazi ukuthi ukuphishekela ikhwalithi ngokungaguquki kuphela okunganikeza amakhasimende umugqa wokukhiqiza ongenakukhathazeka.

Isikhathi sokuthunyelwe: Juni-24-2025