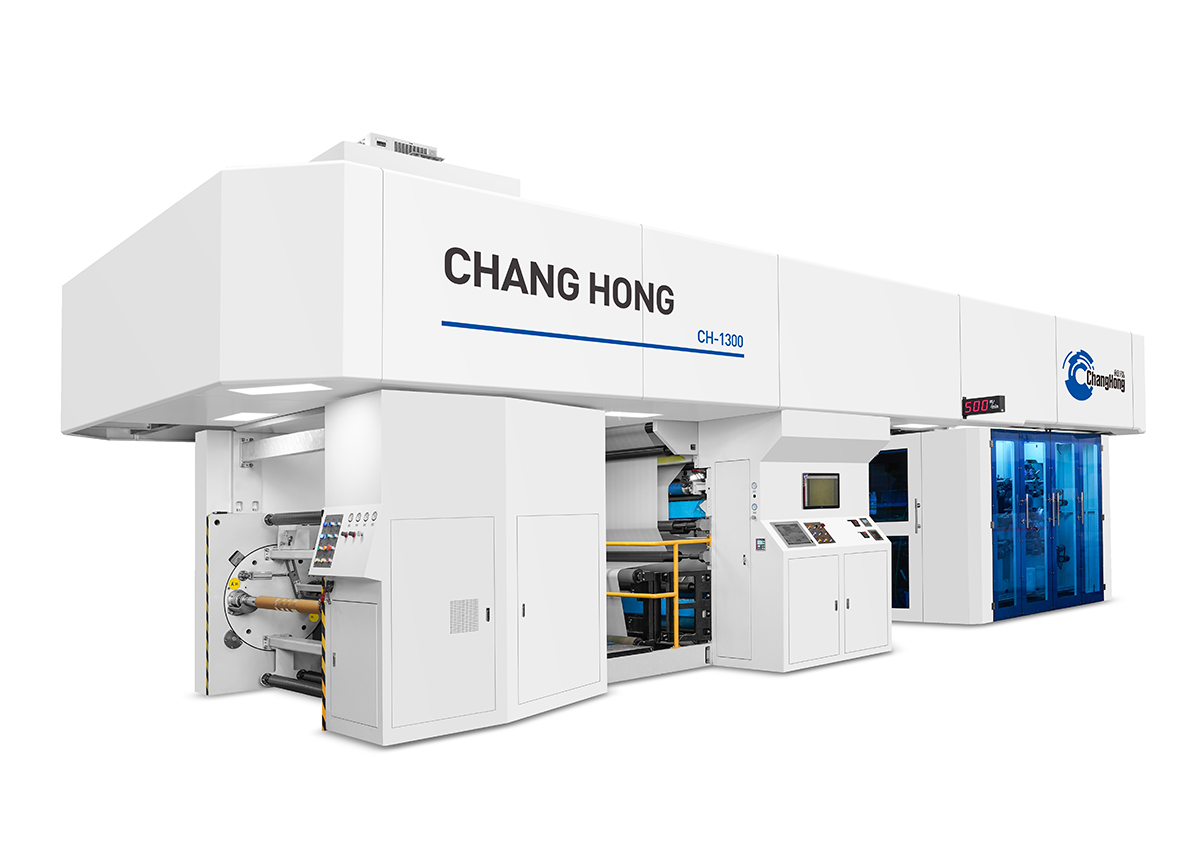

Umshini Wokuphrinta we-CI Flexo

I-CI FLEXO PRINTING PRINTING 6 ENGENAMIBALA

Indlela yomshini wokucindezela we-flexo ongenagiya ithatha indawo yamagiya atholakala kumshini wokucindezela we-flexo ojwayelekile ngohlelo lwe-servo oluthuthukisiwe olunikeza ukulawula okunembile ngesivinini sokuphrinta kanye nokucindezela. Ngenxa yokuthi lolu hlobo lomshini wokuphrinta aludingi amagiya, lunikeza ukuphrinta okusebenzayo nokunembile kunemishini yokucindezela ye-flexo evamile, enezindleko ezimbalwa zokulungisa ezihambisanayo.

Umshini we-Flexo we-CI onemibala engu-8 we-PP/PE/BOPP

Ukufakwa kwe-CI Flexo Machine kutholakala ngokucindezela ipuleti lokusiza irabha noma i-polymer ngokumelene ne-substrate, bese igoqwa phezu kwesilinda. Ukuphrinta kwe-Flexographic kusetshenziswa kabanzi embonini yokupakisha ngenxa yesivinini sayo kanye nemiphumela esezingeni eliphezulu.

Umshini Wokuphrinta we-CI Flexo onemibala emi-4

Umshini Wokunyathelisa we-CI Flexo uwumshini wokunyathelisa odumile osebenza kahle kakhulu owenzelwe ngqo ukunyathelisa ezindaweni eziguquguqukayo. Ubonakala ngokubhaliswa okunembile kakhulu kanye nokukhiqizwa okusheshayo. Usetshenziswa kakhulu ukunyathelisa ezintweni eziguquguqukayo njengephepha, ifilimu kanye nefilimu yepulasitiki. Umshini ungakhiqiza uhla olubanzi lokunyathelisa njengenqubo yokunyathelisa ye-flexo, ukunyathelisa ilebula ye-flexo njll. Usetshenziswa kabanzi embonini yokunyathelisa nokupakisha.

Umshini we-Flexo we-CI onemibala engu-4+4 we-PP Wokulukwa

Uhlelo lokulawula oluthuthukisiwe lwalesi sikhwama esilukiwe se-PP CI Flexo Machine lungafinyelela ukulawulwa kwenqubo yokulungisa amaphutha ngokuzenzakalelayo kanye nokulungisa ukuqhekeka. Ukuze senze isikhwama esilukiwe se-PP, sidinga uMshini Wokunyathelisa we-Flexo okhethekile owenzelwe isikhwama esilukiwe se-PP. Ungaphrinta imibala emi-2, imibala emi-4 noma imibala emi-6 ebusweni besikhwama esilukiwe se-PP.

Umshini wokunyathelisa we-CI ongabizi

Umshini Wokunyathelisa we-Flexo ofingqiwe ngokuthi i-central impression flexography, uyindlela yokunyathelisa esebenzisa amapuleti aguquguqukayo kanye nesilinda sokufaka uphawu esiphakathi ukukhiqiza ukunyathelisa kwekhwalithi ephezulu, okukhulu ezintweni ezahlukahlukene. Le ndlela yokunyathelisa ivame ukusetshenziswa ekulebeni nasekufakeni izicelo, kufaka phakathi ukuphakheja ukudla, ukulebula iziphuzo, nokuningi.

ISITESHI ESINGAMI CI FLEXOGRAPHIC PRINTING PRINTING

Enye yezinzuzo ezibalulekile zalo mshini wokunyathelisa ikhono lawo lokukhiqiza ngaphandle kokuma. Umshini wokunyathelisa we-NON STATION CI flexographic unesistimu yokuhlanganisa ngokuzenzakalelayo evumela ukuthi unyathelise njalo ngaphandle kwesikhathi sokungasebenzi. Lokhu kusho ukuthi amabhizinisi angakhiqiza inani elikhulu lezinto ezinyathelisiwe ngesikhathi esifushane, okuthuthukisa umkhiqizo kanye nenzuzo.

I-CI FLEXO PRINTING PRINTING ENGEYISI-4 EMIBALA

Umshini wokunyathelisa we-flexo ongenagiya uhlobo lomshini wokunyathelisa we-flexo ongadingi amagiya njengengxenye yokusebenza kwawo. Inqubo yokunyathelisa yomshini wokunyathelisa we-flexo ongenagiya ihilela i-substrate noma izinto eziphakelwa ngochungechunge lwama-roller namapuleti abese efaka isithombe esifiselekayo ku-substrate.

I-CENTRAL IMPRESSION FLEXO PRESS YOKUPHAKISHA UKUDLA

I-Central Impression Flexo Press iwumshini omangalisayo wobuchwepheshe bokunyathelisa oye washintsha imboni yokunyathelisa. Ingomunye wemishini yokunyathelisa ethuthuke kakhulu etholakala emakethe njengamanje, futhi inikeza izinzuzo eziningi ezenza kube ukukhetha okukhangayo kwamabhizinisi abo bonke osayizi.

Umshini we-Flexo we-CI onemibala emi-6 wefilimu yepulasitiki

Umshini Wokunyathelisa we-CI Flexo uhlobo lomshini wokunyathelisa osebenzisa ipuleti lokusiza eliguquguqukayo ukunyathelisa ezinhlotsheni ezahlukene ze-substrate, okuhlanganisa iphepha, ifilimu, ipulasitiki, kanye nama-foil ensimbi. Usebenza ngokudlulisela uphawu oluyinki ku-substrate ngesilinda esijikelezayo.

Umshini wokucindezela we-servo ci flexo ogcwele wendebe/iphepha elingelona elokwelukiweyo/iphepha

Umshini wokunyathelisa we-flexo ongenagiya uhlobo lomshini wokunyathelisa osusa isidingo samagiya okudlulisa amandla kusuka kumoto kuya kumapuleti okunyathelisa. Esikhundleni salokho, usebenzisa i-servo motor eqhutshwa ngqo ukunika amandla isilinda sepuleti kanye ne-anilox roller. Lobu buchwepheshe buhlinzeka ngokulawula okunembe kakhulu inqubo yokunyathelisa futhi kunciphisa ukulungiswa okudingekayo kwemishini yokunyathelisa eqhutshwa yigiya.

Umshini Wokunyathelisa we-Central Drum 6 Color CI Flexo Wemikhiqizo Yephepha

Umshini Wokunyathelisa we-Central Drum Flexo uwumshini wokunyathelisa we-Flexo othuthukisiwe ongaphrinta ihluzo nezithombe ezisezingeni eliphezulu ezinhlotsheni ezahlukene ze-substrate, ngesivinini nangokunemba. Kufanelekela imboni yokupakisha eguquguqukayo. Wenzelwe ukunyathelisa ngokushesha nangokusebenza kahle kuma-substrate ngokunemba okuphezulu, ngesivinini esikhulu sokukhiqiza.